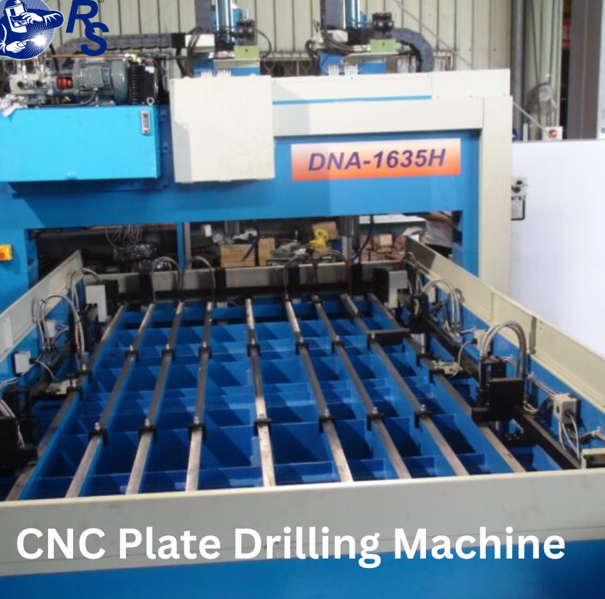

CNC Plate Drilling Machine: Smart, Sustainable, and Precise Metal Processing

As industries move toward greener and more efficient manufacturing, machines that combine precision with sustainability are becoming essential. A CNC Plate Drilling Machine is a modern solution that delivers high-accuracy drilling while reducing material waste, energy consumption, and manual intervention.

Designed for heavy plates and structural components, this machine supports eco-friendly production without compromising on performance or productivity.

What Is a CNC Plate Drilling Machine?

A CNC Plate Drilling Machine is an automated machining system used to drill holes in metal plates with extreme accuracy. Controlled by computer numerical control (CNC), it ensures consistent hole positioning, depth, and diameter across every workpiece.

By minimizing errors and rework, CNC plate drilling significantly reduces raw material waste—making it a sustainable choice for modern fabrication facilities.

Eco-Friendly Advantages of CNC Plate Drilling Machines

Reduced Material Waste

High-precision drilling eliminates misaligned holes and scrap plates, conserving valuable raw materials.

Energy-Efficient Operation

Optimized CNC programming and servo-driven systems reduce power consumption compared to conventional drilling methods.

Longer Tool Life

Accurate cutting parameters minimize tool wear, reducing the frequency of tool replacement and industrial waste.

Minimal Rework & Emissions

Fewer rejected parts mean less reprocessing, lower energy use, and reduced carbon footprint.

Key Features of a CNC Plate Drilling Machine

Advanced CNC Control System

Ensures repeatable accuracy, intelligent drilling cycles, and automated positioning.

Multi-Spindle or High-Speed Drilling

Boosts productivity while maintaining precision across thick and heavy plates.

Rigid & Vibration-Free Structure

Heavy-duty construction improves accuracy and reduces noise pollution.

Automatic Clamping & Positioning

Minimizes manual handling, improving workplace safety and efficiency.

Smart Programming Interface

Easy CAD/CAM integration allows optimized material usage and efficient job planning.

Benefits for Modern Fabrication Industries

- High-precision hole drilling

- Faster production cycles

- Reduced energy and material consumption

- Lower labor dependency

- Cleaner and safer working environment

- Supports sustainable manufacturing goals

Applications of CNC Plate Drilling Machines

CNC Plate Drilling Machines are widely used in:

- Structural steel fabrication

- Pre-engineered building (PEB) systems

- Wind energy and renewable projects

- Bridge and infrastructure construction

- Heavy engineering and industrial equipment manufacturing