Nerolac Industrial Paint in Mohali is a trusted and widely used solution for protecting industrial assets, machinery, and structures from corrosion, chemical exposure, and harsh environmental conditions. Designed with advanced coating technology, Nerolac industrial paints offer superior durability, excellent adhesion, and long-lasting performance, making them ideal for a wide range of industrial applications in Mohali and surrounding industrial areas.Advanced Protection for Industrial Environments

Nerolac industrial coatings are engineered to withstand extreme operating conditions, including high humidity, temperature variations, chemical exposure, and mechanical wear. These paints create a tough protective layer that prevents rust, corrosion, and surface degradation, ensuring long-term protection for metal and steel surfaces commonly used in industrial setups.

Key Features of Nerolac Industrial Paint

- Excellent rust and corrosion resistance

- High durability and long service life

- Strong adhesion on metal and industrial surfaces

- Resistance to chemicals, oils, and solvents

- Smooth and uniform finish

- Suitable for indoor and outdoor industrial use

Wide Range of Industrial Applications in Mohali

Nerolac industrial paints are suitable for multiple industries and applications, including:

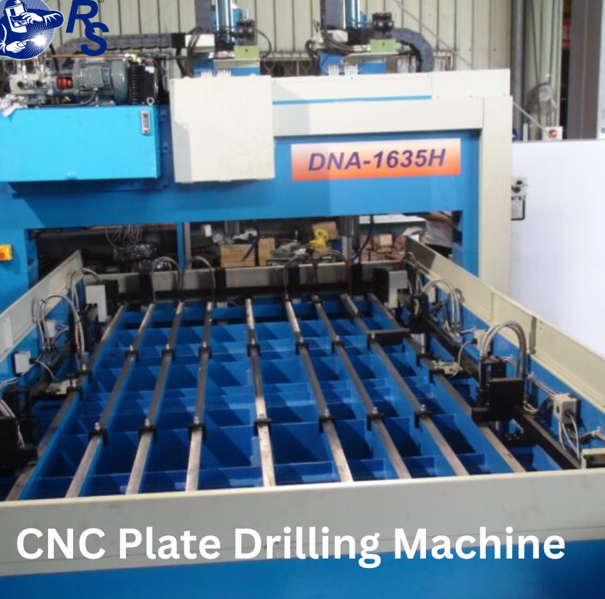

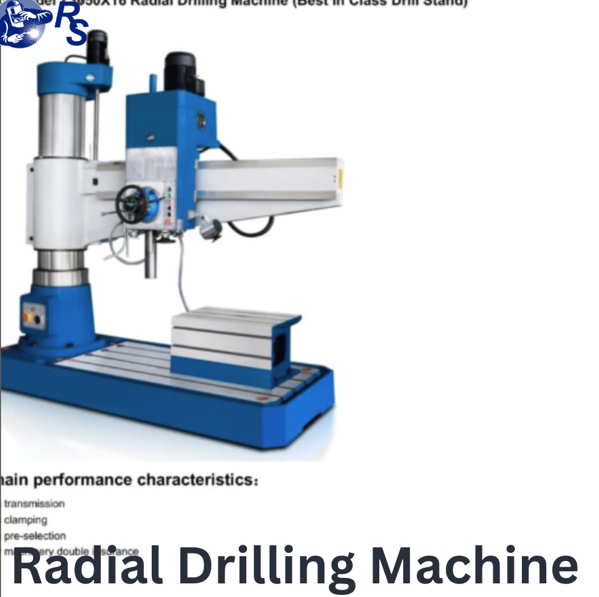

- Heavy machinery and industrial equipment

- Steel structures and fabrication work

- Industrial pipelines and storage tanks

- Automotive and engineering components

- Power plants, warehouses, and factories

These coatings help industries in Mohali reduce maintenance costs, minimize downtime, and improve overall operational efficiency.

Why Choose Nerolac Industrial Paint in Mohali?

Nerolac is a well-established brand known for quality, innovation, and reliability. Its industrial paint solutions are developed using modern technology to deliver consistent performance and superior protection. Whether it is primers, enamels, epoxy coatings, or PU paints, Nerolac offers complete coating systems tailored to industrial needs.